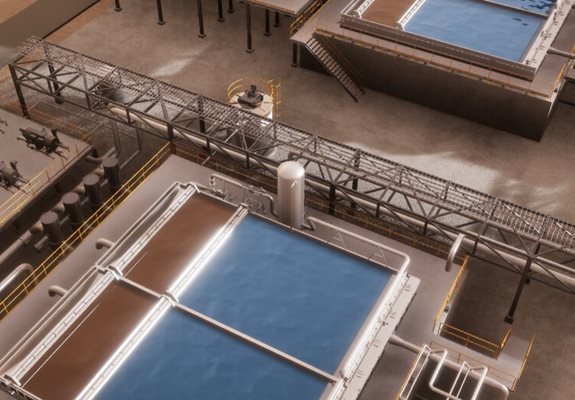

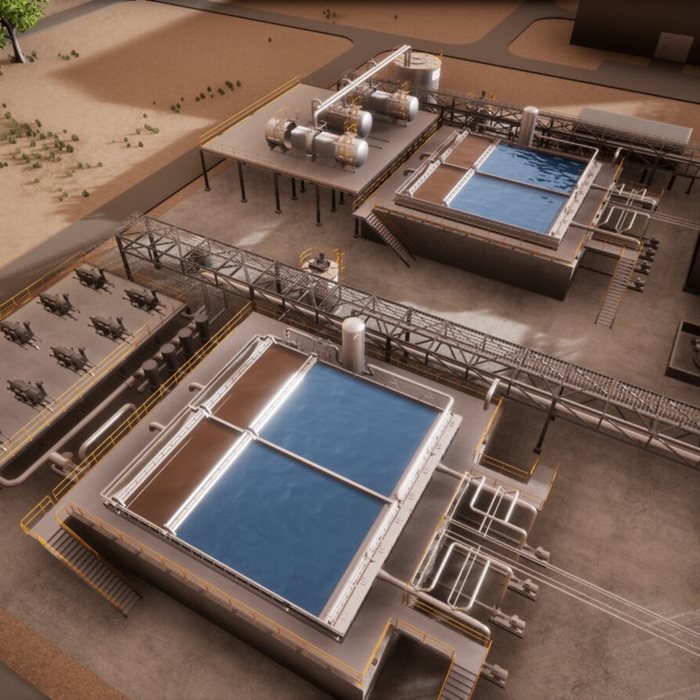

Modular plant

Process Water Recycling Plant is a modular solution based on predesigned water treatment units and parts. It is especially targeted for concentrator plants where the tailings are dewatered, and water usage is changing to ‘short recycle’-water streams. The plant is fully configurable for each process depending on the requirements, and we offer a full range of complementary services including process assessment, laboratory and pilot scale testing and analysis, technical studies, and remote monitoring and support.

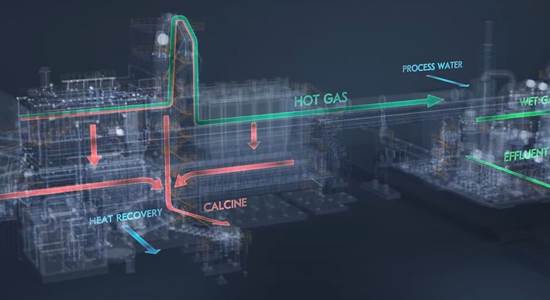

Microflotation

Microflotation is a highly efficient dispersion water system suitable for various water or effluent clarification applications. The system offers excellent performance for fluctuating process water recycling with low maintenance requirements. Microflotation is a well-known method of particle separation. Air is dissolved in water under pressure, forming microbubbles when the pressurized water is released. Chemical, physical, and electrical forces cause the suspended solids and colloids to attach to the air bubbles and each other. These particle flocs then float to the surface and are scraped off. Coagulation or flocculation chemicals are used to enhance the process. Metso Rapid Mixer ensures an efficient mixing of chemicals leading to savings in chemical consumption.

Polishing filters

Metso Larox® LSF polishing filters remove and recover solids in low concentrations from process liquids. The quality of the resulting filtrate increases production capacity and the quality of plant end products. Effective and economical, based on the principal of adsorption filtration and constructed to an advanced filter design, Larox LSF cost-effectively reduces suspended solids to very low levels of parts per million (ppm) in the filtrate exiting the unit.

During filtration, the process liquid is fed to the vessel and liquid passes through the cloth at a low velocity, leaving the particles on the fabric and only allowing clear filtrate to pass through. Pumping at constant flux, the initial pressure is low and this slowly increases as a cake builds on the elements.

Liquid filters

Metso Screen Omega filters are large, self-cleaning automatic filters for fine filtration. The simple and robust construction with suction scanning mechanism and a multiscreen design make them perfect for filtering high-flow and poor quality water to very fine filtration degrees down to 10 micron.

Metso Microfiber AMF filters are innovative, self-cleaning microfiber water filters for treatments as fine as 2 microns. The filters provide cartridge filter performance without the need for cartridge filter replacement, outperforming traditional sand media systems.