- Detailed wear report

- One-on-one consultation follow-up

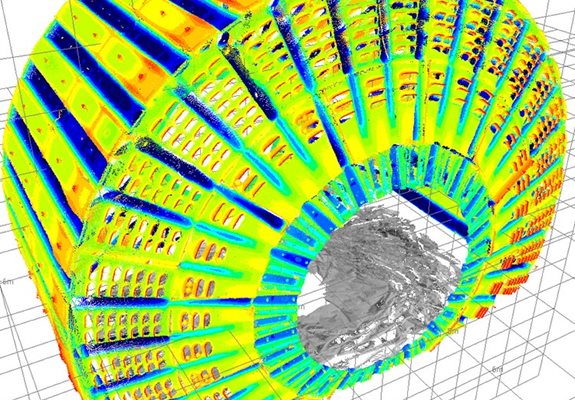

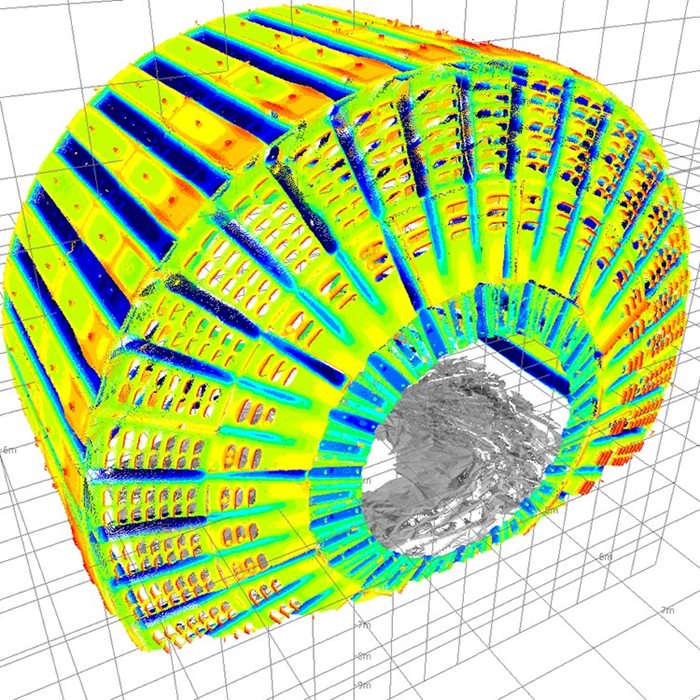

- 3D model and software

- Database package of site’s wear history

Scanning is performed in as little as 15 minutes and can be scheduled to coincide with your planned inspection shutdown.

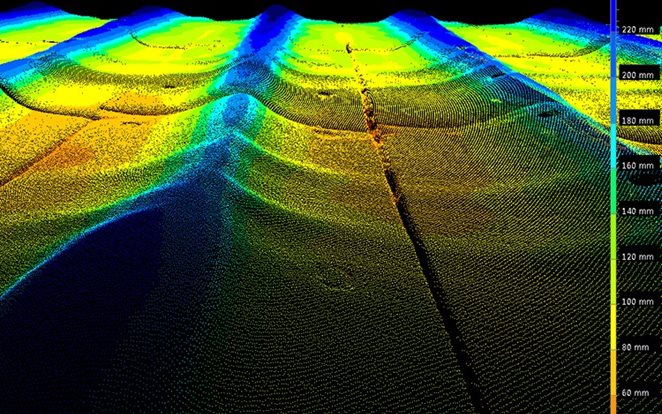

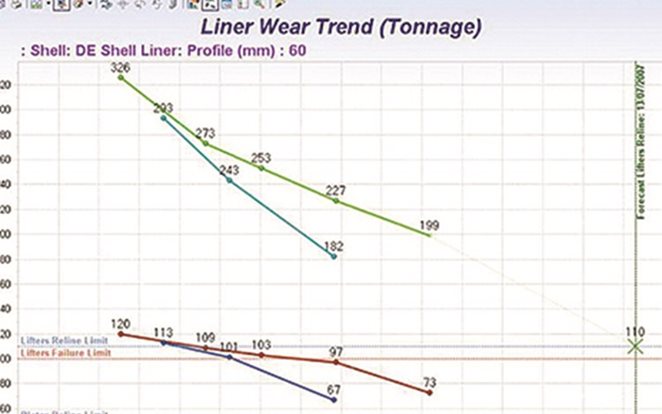

The wear report, provided in a very short time frame, provides statistical wear tracking information, including wear curves, forecasting tables, cross-sectional and longitudinal profile curves, and reline efficiency. Metso MillMapper liner wear monitoring software automatically selects and reports on the highest wearing zone, giving you protection against unexpected wear patterns and ensuring that high wearing areas are always captured.

The report is written by a metallurgist or engineer, followed by recommendations in a one-on-one consultation. Sites are also encouraged to download the 3D models and reports from their scan, using the integrated Metso MillMapper software. They can then conduct a virtual inspection of the mill and comprehensively review any particular point.

Metso can also be commissioned for project work to optimize mill operation, optimize the sequencing of reline schedules, redesign liners, calibrate load cells, perform a complete reline service for grinding mills, and much more.

We are proud of our 60+ years of experience in optimizing grinding mill liners and implementing best practices. Metso offers the market’s widest range of products to choose from.