Performance targets

Durable, high-performing screening media designed with safety as the top priority

Shorter and fewer maintenance stops

Reaching quality targets and maximizing production efficiency

Global expert network with extensive comminution knowledge

We help you choose the right media for your application

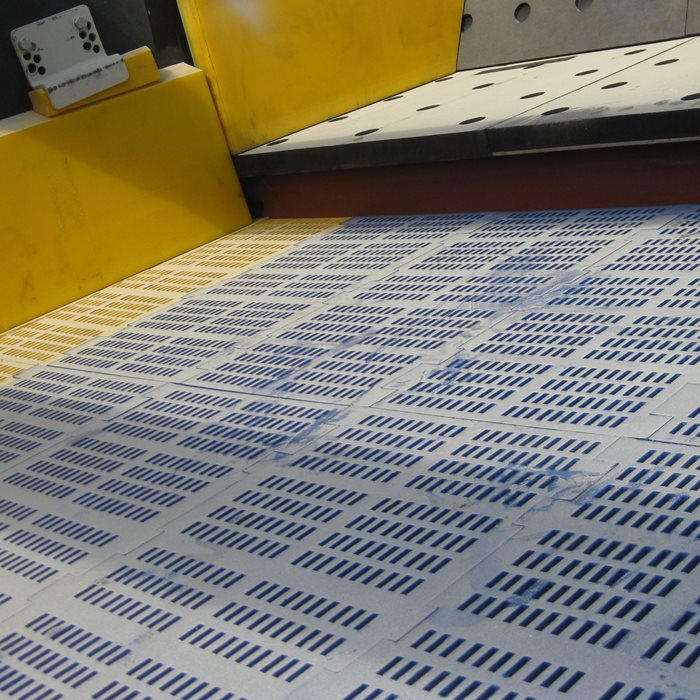

With solutions that range from rubber and polyurethane to classic wire, Metso offers versatile screening media systems that provide performance and cost effectiveness for a wide range of screening applications. We offer Modular systems, Panel systems and Tension systems.

We can help you find the optimal solution by looking at your screening process, application and targets.

Learn more about our different systems

We have categorized the selection based on common challenges:

Availability

Standard range

Always available, quickly and conveniently, wherever you are

HiPer Clean

Precision production without interruptions, guaranteed to stay clean

HiPer Flow

At least 20% more active screening surface

HiPer Life

Built tough for maximum load handling

Screening media offering

{{decodeHtmlEntities(field.label)}} |

|---|

More than screening media

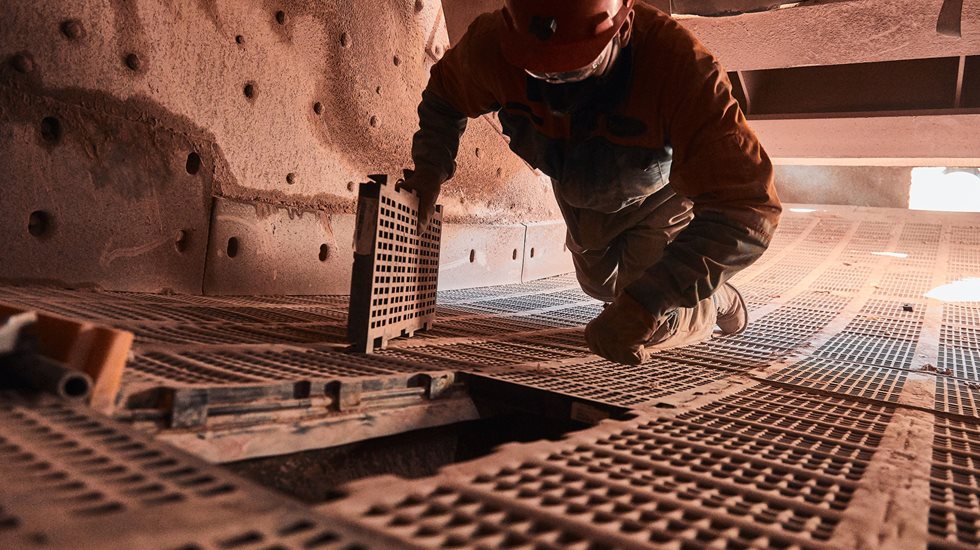

Milpillas, Mexico